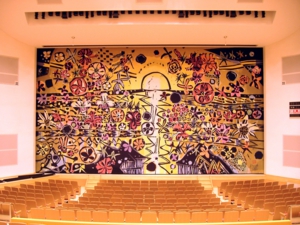

緞帳の制作工程

緞帳ができるまで

1 Design, Rough Sketch

デザイン・下絵

The space in which the drop curtain is to be installed is first examined,

taking into consideration such factors as the onsite conditions, including

the lighting, the type of use, and the use, how much the organizations

commissioning the curtain wants to control the space, including any theme or ideas they might suggest, and then the design is determined and original drawing is made.

ホール空間の調査を行い、採光、用途、サイズなどの環境条件、空間演出の意図、テーマに沿ってデザインが決められ原画が描かれます。

2 Choosing the Thread, Matching the Colors

糸だし・色合わせ

To begin, the colored thread that will become the most important base

colors are selected to mach the original drawing. The actual threads to

be used in weaving of the drop curtain then are chosen by craftsmen with long experience on the basis of the quality, color, and volume of the

threads.

原画を元に幾色もある色糸の中からもっとも基本色となる糸色を探り、色合いを合わせてゆきます。緞帳を織るために必要な糸の質感、糸の色、糸の量が職人の長い経験に養われた勘から決まります。

3 Dyeing and Twilling of the Thread

糸染色・撚糸

When the threads to be used in the drop curtain have been selected,

The threads are then dyed very carefully by hand. Because the dyestuffs

create very slightly different colors each time, the amounts of thread needed for each color are first determined, and all the threads of each color are dyed separately in single batches. This process is accomplished

by master artisans. Nest, the fine threads that have been dyed are placed

in a twilling machine, that twists several strands(normally 5 threads)

into twilled threads. Through the subtle combination of threads of different colors, it is possible to prepare from between 300 and 500 colored twilled threads for a single curtain, resulting in palette of hues as fine as could be created through the mixing of paints.

緞帳に使われる糸が決ると、糸を丹念に手染めしてゆきます。染料は時を違えると微妙に色合いが異なるため、使われる量を判断して色毎に染めるのです。これも職人の腕によります。次に染め上がった細い糸を機械に掛け、数本(基本は5本)を一本の撚糸に仕上げます。微妙な色彩を表現する為、一作品にて約300~500色もの撚糸が用意されます。まるで絵の具を混ぜ合わせたような繊細な色糸の出来上がりです。

4 Sample Weaving

試し織

In order to see the pile, color and quality design when woven, a sample

is test woven before the actual weaving takes place. This process is essential in the weaving of huge woven tapestries.

デザインの風合い、色彩、質感を観るために本織りの前に試し織りをします。巨大な緞帳を作成するにあたり、欠かせない工程です。

5 Expanding the Drawing

拡大

The pattern is created from the original drawing by a Rotring, and a rough sketch is made in the actual size. The detailed operation, which

must expand the drawing faithfully, is drawn very carefully over several

months, proceeding by drawing one section at a time.

ロットリングによって原画から型起こしし、原寸大に下絵(設計図)を描いてゆきます。原画を忠実に引き伸ばすという緻密なこの作業は、数ヶ月をかけて手でひとつひとつ進めてゆきます。

6. Weaving the Curtain

製織

Following the design sketch, the shuttle, which is threaded with the weft, is passed by each warp one at time in order to create the design in

a type of horizontal weaving. The weft employs threads of two or more

different colors, the use of which naturally creates a curtain which a wonderful pile. All operations are conducted by hand, and the work of a great number of craftsmen is necessary. In spite of that, only very little

can actually be woven in a single day, such that it requires about six months to complete a single curtain.

下絵に従って経糸に、色糸ごとに杼に通した緯糸を模様の部分を綴るように織り込んでゆきます。縦糸は複数の色糸が用いられ、それが織り上がったときに素晴らしい風合いを醸し出すのです。作業は全てが手作業であり

大勢の人の手を要します。それでも一日に織り上がるのは僅かで、約半年の時がかかるのです。

7 Stitching and Finishing

縫製・仕上げ

As the tapestry is being woven, the weft sometimes folds back upon itself depending upon the color or the design. Because of that, a space is created between such foldings back that is called hatsuri. In order to finish the work, these spaces are closed up by a technique akin to hem stitching. After that, the work is completed through such processes as cleaning the surface, sewing the four edges, attaching the backing, adding the bottom fringe, and attaching the lead ropes to the top.

綴織は緯糸を色や模様によって折り返して織られます。そのために折り返しの部分と部分に「はつり」と呼ばれる隙間ができます。仕上げは、この「はつり」をかがり縫いして閉じてゆきます。その後、裏面の清掃、四方の釘打、下部フレンジ付け、上部チチヒモ付けという工程を経て完成します。